What is the function of a coping in building construction

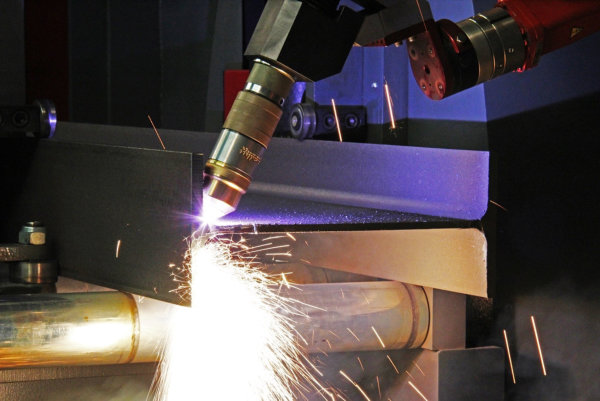

The Robotic Coping/Profiling system is an equivalent of an automated fabrication process. It can handle the following processes: beam drill lines, angle lines, hydraulic punches and ironworkers. This is just one way to make your fabrication processes more efficient.

Our factory-trained service tech will spend 5 days on the job installing your machine, calibrating and retraining your operators. This will allow for more hands-on operation as well as troubleshooting and diagnostic training.